Aluminum Raised FloorTechnical Sector

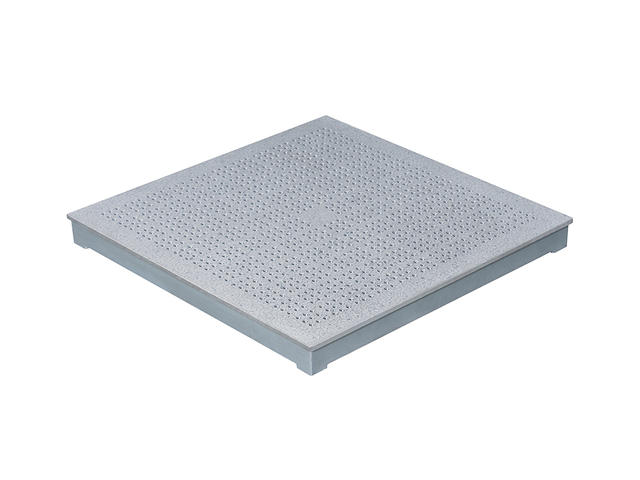

FINECO Aluminum Raised Floor panels are sand-blasting finished, consisting of pressure casting aluminum alloy with well-designed strengthening ribs backside. Manufactured with high precision, these fire proof and rigid panels deliver the ultimate in static control, strength, durability, and acoustic performance. FINECO has a full range of panels to meet standard as per CE and CISCA testing methods and an extensive selection of understructure. For further information on product details, architectural details, system specifications, select the proper panel to meet the needs of your specific application.

FINECO aluminum raised floor intended for data centers and advanced manufacturing facilities with a wide range of load requirement and is engineered to meet FINECO standard as per CE& CISCA testing methods.

Key Performance

Full aluminum die-casting structure, light weight, no ferrous materials to disrupt magnetic fields

Perforated panels and grates provide a variety of open area percentages

High dimensional precision, high loading, designed for advanced manufacturing facilities, data centers and other industrial applications

More stable static performance, compared with steel or galvanized steel material

High flexibility to adapt to a updating application, reusable in different locations

Non-combustible material , Class A fire proof rating

Technical Data

Model | Concentrated Load | Ultimate Load | Uniform Load | Surface Treatment | Top Finish | |

|---|---|---|---|---|---|---|

KG | N | N | N/㎡ | Shot blasting/Epoxy coating | Bare/HPL/PVC | |

| FCA500 | 500 | 4900 | 9800 | 14700 | ○ | ○ |

| FCA700 | 700 | 6860 | 13720 | 20580 | ○ | ○ |

| FCA1000 | 1000 | 9800 | 19600 | 29400 | ○ | ○ |

| FCA1200 | 1200 | 11760 | 23520 | 35280 | ○ | ○ |

| FCA1500 | 1500 | 14700 | 29400 | 44100 | ○ | ○ |

| FCA2000 | 2000 | 19600 | 39200 | 58800 | ○ | ○ |

| FCA2500 | 2500 | 24500 | 49000 | 73500 | ○ | ○ |

| FCA3000 | 3000 | 29400 | 58800 | 88200 | ○ | ○ |

* According to CE& CISCA's recommended test procedures for Access Floors

FINECO aluminum airflow panel ventilation rate: 30%, 50% and 55%

600*600mm available

Why the aluminum raised floor system?

Though the galvanized overlay prevents corrosion, the molecular stress created by this electroplating process causes the zinc to sometimes expand outward, and in the process, create filaments commonly referred to as zinc whiskers which will greatly decrease the static performance of a raised floor system. Meanwhile if zinc whiskers physically detach from their surfaces and enter a data center’s airflow, these electro-charged particles can cause short circuits and other equipment failure.

You may consider accessories with hot-dip galvanizing or a powder coating but still an aluminum raised floor system is the best option with utmost stability. The inclusion of an aluminum raised floor system, airflow panel, grommet, outlet box, cable tray, fiber channel, structural ceiling and modular wall in the manufacturing facility all help to meet the demands of evolving advanced manufacturing today, while still meeting the everyday needs of security and reliability.